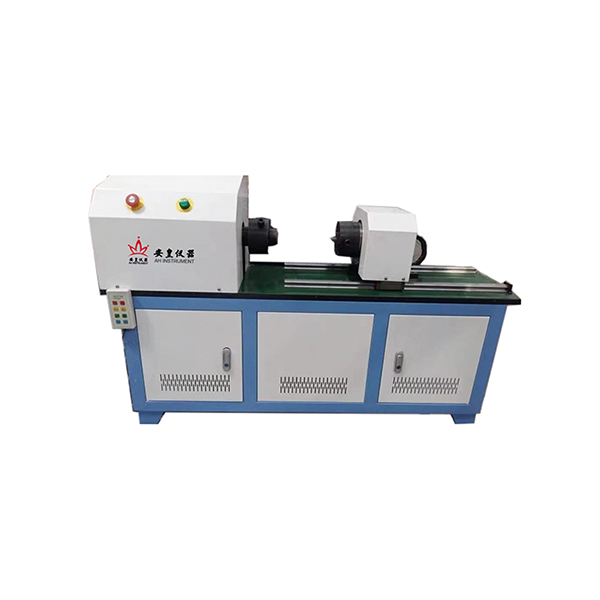

Torsion Testing Machine

Summary:

- This torsion tester is suitable for static torsional testing of metal materials, non-metal materials and various components such as drive shafts, half shafts, various spanners, hardware tools, bolts and nuts, bi-metal materials and bonded parts.

Details About Torsion Testing Machine

Summary:

- This torsion tester is composed of loading system, transmission system, digital data acquisition and processing system, computer measurement and control display system.

- The machine has a horizontal structure, computer control and screen display, digital data acquisition and control system, and a fully digital AC servo system.

- Adopting planetary cycloid reducer drive, it has the characteristics of uniform and stable loading, no impact phenomenon and accurate data acquisition control.

- Test functions: WindowsXP operating platform, to achieve a variety of control of torque, torsion angle, deformation. Use of Windows type operating system with graphic interface, display screen and operation panel can be set, test speed and various control parameters can be set, basic test results can be displayed in real time, various related curves of the test process can be displayed in real time, system diagnostics can be realized and diagnostic results can be displayed.

- The machine usesa fully digital AC servo control system and a digital data acquisition and processing system, with photoelectric encoders collecting the twisting and turning angle of the specimen.

Technical parameters:

- Max torque: 500, 1000, 2000, 3000, 5000 Nm

- Tester level: Level 1

- Torque measurement range: 1%~100%FS(Max. torque)

- Relative error of test torque indication: ≤ ±1% of indicatingvalue

- Torque resolution: 1/300,000 of the Max. torque, no staging throughout

- Torsion angle measurementdevice: Optical encoder

- Relative error of torsion angleindication: ≤ ±1% of indicating value

- Torsion angleresolution: 0.05-999.9°/Min, Stepless speed regulation

- Relative error of torsion speed: ≤ ±1% of indicatingvalue

- Torsion direction: Forward,reverse

- Safety protection: Mechanical limit protection and software overload protection

- Data collection and processing by computer, printing of standard report formats, and historical search capability

Share Torsion Testing Machine With Others

Share to Facebook

Share to Twitter

Share to LinkedIn

Share to Pinterest

Related products

Electro-hydraulic Universal Material Tester AH41055

Check Details This product has multiple variants. The options may be chosen on the product page