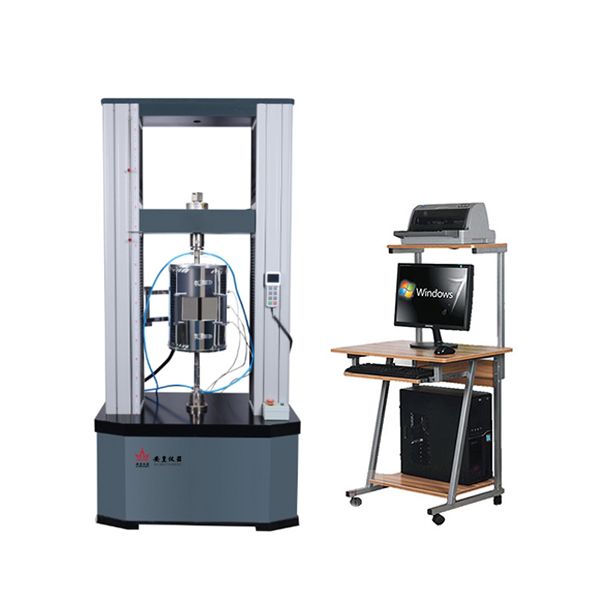

High Temperature Tensile Testing Machine

Summary:

This high temperature tensile testing machine is equipped with a computer, can automatically controls the rising, falling, testing, and stopping of the equipment. The equipment has beautiful appearance, convenient operation, and stable and reliable performance.

Details About High Temperature Tensile Testing Machine

Summary:

The high temperature tensile testing machine is manufactured according to the standards of GB/T2611-2007 “General Technical Requirements for Testing Machines” and GB/T16491-2008 “Electronic Universal Testing Machine”.

Usage:

This machine is mainly used for tensile, compression, peeling, shearing, tearing and bending mechanical properties tests of metal and non-metallic materials. Widely used in aerospace, petrochemical, machinery manufacturing, plastic rubber, ceramic building materials, metal materials, construction engineering and other industries, as well as institutions of higher learning, scientific research institutions, technical supervision, quality inspection stations and other departments.

Technical parameters:

- Test force

- Max test force: 100KN, can be selected according to user needs

- Tester measurement accuracy: Level 1 (standard) / Level 0.5 (optional)

- Effective measurement range: 2%-100%FS (Level 1) / 4%-100%FS (Level 0.5)

- Resolution: 1/300000

- Relative error of indication: ±1% (Level 1) /±0.5% (Level 0.5)

- Test speed

- Speed adjustment range: 05~500mm/Min, stepless speed regulation, (can be selected according to user needs)

- Accuracy: ≤ ±1% of the indicated value

- Force control speed control range: 05-5%FN

- Force control speed control accuracy:

- When speed <0.05FN/s: Within ±2% of the set value

- When speed ≥0.05FN/s: Within ±1% of set value/ ±0.5% (level 0.5)

- Deformation rate control range: 05-5%FN

- Deformation rate control accuracy:

- When speed <0.05FN/s: Within ±2% of set value

- When speed ≥0.05FN/s: Within ±0.5% of set value

- Displacement(moving beam)

- Measuring range: 0~999mm

- Resolution: 001mm

- Measurement accuracy: ≤ ±1% of the indicated value

- Deformation

- Big deformation measurement range: 10-800mm (or according to user needs)

- Small deformation measurement range: Gauge length: 50mm, Max deformation: 15mm (or according to user needs)

- Effective measurement range: 2%~100%FS

- Resolution: 01mm

- Relative error of indication: ±1%

- Test space

- Effective tensile space: 700mm (or according to user needs)

- Effective compression space: 700mm (or according to user needs)

- Effective test width: 550mm (or according to user needs)

- High temperature oven

- Structure: Split structure resistance furnace, using three-section electric furnace wire heating, segmented control

- Working temperature range: 200~1000℃

- Effective uniform temperature zone length: 100mm

- Inner size: φ90×290mm (approximately) (or according to user needs)

- Outer size: φ320×380mm (approximately) (or according to user needs)

- Wire (electric heating element): φ1.2mm furnace wire

- Power supply: 380V

- Service life: Continuous working time:>30,000 hours, T: ≤1000℃

- Moving mode:Manual rotation

- Temperature accuracy:

- Test T.: 200~600℃: T. fluctuation: ±3°C, T. gradient: 3°C

- Test T.: 200~600℃: T. fluctuation: ±4°C, T. gradient: 4°C

- Test T.: 900~1100℃: T. fluctuation: ±5°C, T. gradient: 5°C

Share High Temperature Tensile Testing Machine With Others

Related products

Tensile Tester Universal Testing Machine

Check Details This product has multiple variants. The options may be chosen on the product pageUniversal Testing Machine Tensile Tester

Check Details This product has multiple variants. The options may be chosen on the product page