1.Test Steps

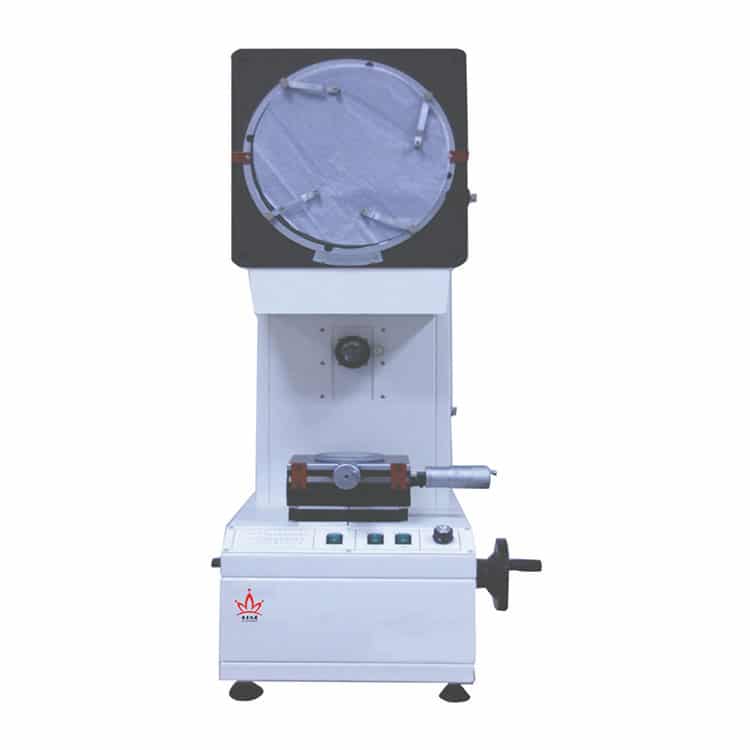

(1) Check the correctness of each part of the equipment and the cleanliness of the work surface, adjust the brightness of the lighting, etc.

(2) Cut the insulated or sheathed sample into thin slices (not more than 1mm) with a blade and place it on the glass of the measuring table. Adjust the lens barrel up and down until a clear image of the sample is obtained from the eyepiece.

(3) Rotate the vertical and horizontal worktables and manually raise and lower the handwheel to make the worktable move up and down, and adjust the thickness and thickness until the measuring point of the sample is seen from the eyepiece. The absolute value of the difference between the two data of the measuring device is the measured thickness. The amount of movement can be displayed on the digital display box and make a record.

(4) After the measurement, clean the equipment.

2. Precautions

(1) When using or storing the instrument, avoid dust, moisture, excessive cooling, overheating, and gases containing acid or alkali. The storage place or room should be kept at 20℃±5℃.

(2) Lenses should be wiped with cotton wool or lens paper.

(3) The mechanical transmission part of the instrument should be properly lubricated, and if necessary, the grease should be clear and replaced.

(4) In order to maintain the accuracy of the instrument, apart from the moving parts of the work, the disassembly and repair of other parts should be carried out by professionals.