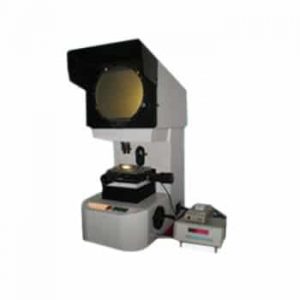

Optical Image Measuring Instrument

Optical Image Measuring Instrument is widely used in all fields of application with two coordinates for the purpose, such as machinery, electronics, instruments, and plastic, etc.

| Accuracy | (3+L/75)µm L: length of the tester, units: mm |

|---|---|

| Temporal resolution | 0.001mm |

| Repeatable accuracy | 0.002mm |

| Eyepiece | 0.5X (Optional: 1X, 2X) |

| Objective | 0.7X-4.5X |

| Magnification | 20X-120X |

Details About Optical Image Measuring Instrument

Features:

- Varifocus objective and graticule marker generator as the measurement aiming system.

- Various data processing and display, input and output functions, especially the function of adjusting sample is very useful.

- High resolution and set times for the objective, to change the rate doesn’t need to rechoose the scale.

- Spare R232 interface, the specialized software can deal with and output the surveying and mapping graphics after conecting with computer.

Standard Function:

- Can take pictures of the products, and store in the computer to form a product atlas as the form of jpeg.

- Compare the photos stored in the computer with the Real-time images in the same screen.

- The pictures can be input to AutoCAD to become an engineering drawing.

- AutoCAD standard engineering drawings can be input into real-time image, making AutoCAD engineering drawings and the actual shape overlap, then compare them, as to find out their difference.

- Can input previously stored jpeg image to the real-time image.

- Can dimensioning in bird’s eye view of the map.

- Customer-defined circle: make a standard circle according to clients’ needs, and then compare the standard circle with the actual sample overlapped, so as to find the error between them.

- Customer-defined segment: can define the starting point coordinates, length, and rotating angle of the segment, and then compare with the actual sample overlapped, so as to find the error between them.

- Customer-defined coordinate: define the Coordinates origin as (0, 0) in the Actual sample of the real-time image, then Mark any point of the picture’s coordinate position.

- Dim ordinate: To make the self-defined origin (0, 0) as a benchmark, and then mark any point of the picture’s coordinate position.

- Patent taking R Angle function: accurate plane taking R Angle mode in the present market condition.

- Measurement: can measure any physical dimension in the plane. (Angle, diameter, radius, distance of point to the line, two round eccentric, and distance between two points)

- Plotting: can describe the shape of the actual sample in the Real-time image, and then form a complete engineering drawing. (Drawing mode is similar to AutoCAD)

- Mark: Can mark any physical dimension in real-time image. (Length, angle, diameter, radius, distance of point to the line, and distance between two points)

Technical parameters:

| Type | 1510 Manual | 2010 Manual | 3020 Manual | 4030 Manual |

| Dimension (mm) | 600*500*850 | 600*500*850 | 850*600*900 | 970*670*940 |

| Metal table dimension (mm) | 345*250 | 345*250 | 450*350 | 650*350 |

| Glass table dimension (mm) | 220*150 | 220*150 | 340*240 | 480*370 |

| Actual working stroke (mm) | 150*100*120 | 200*100*130 | 300*200*150 | 400*300*150 |

| Weight (KG) | 100 | 110 | 200 | 250 |

- Cabinet base: Granite: Level 00 Granite

- Accuracy: (3+L/75)µm L: length of the tester, units: mm

- Surface lighting: LED annulus super bright UHP (brightness is adjustable)

- Silhouette lighting: LED super bright circular lamp (brightness is adjustable)

- Calculation and measurement: REICA 2.5D Precise-measurement software

- Temporal resolution: 0.001mm

- Repeatable accuracy: 0.002mm

- CCD: SONY chip, 1/3 colorful CCD

- Eyepiece: 0.5X (Optional: 1X, 2X)

- Objective: 0.7X-4.5X, Magnification: 20X-120X

- Power supplier: AC90-264V, 50/60Hz

- Carrying capacity: 30KG

- Operation mode: By hand (Micro adjustment and quick movement)

Share Optical Image Measuring Instrument With Others

Share to Facebook

Share to Twitter

Share to LinkedIn

Share to Pinterest